Fiberglass Boat Repair in Seattle

Like everything else boats can deteriorate over time

The marine environment is unforgiving. UV rays from the sun, and even just time, can cause bedding to fail around hardware and under teak decks, allowing water to get into the core between the outer and inner fiberglass skins of the deck or cabin top, eventually causing it to rot, severely affecting itsstructural integrity, and causing water damage to interior finishes.

Boat Accidents will happen

Boat handling can be challenging at times. A strong cross wind or a current can cause even a competent and experienced skipper to hit the dock, scraping the hull. Even when securely moored in its slip or at anchor a boat is occasionally hit by a less experienced neighbor. Anchors can drag causing boats to collide with one another, or with the bottom. There are floating logs, uncharted rocks, and occasionally storms strong enough to break boats free from their moorings.

Northwest Marine fiberglass is an expert at fiberglass boat repair.

At Northwest Marine Fiberglass we have the skills, experience, and product knowledge to handle any fiberglass repairs necessary to return your vessel to its original condition, inmost cases better than original condition

Dock Rash

Chips, dings, and scrapes in the topsides, commonly referred to as “dock rash” are usually just cosmetic, having no real structural significance, nevertheless they are upsetting and even embarrassing to a proud boat owner. This type of damage can be handled by making spot repairs, either paint or gelcoat. When done correctly the perfect color match and finish blending lead to a repair that is undetectable.

Structural fiberglass hull repair resulting from a collision or grounding.

A grounding or collision can cause damage that affects the strength and even seaworthiness of the hull. Structural fiberglass repairs require more labor and materials than simple cosmetic repairsand require a longer stay in the boatyard. The work area must be tented off and the ground covered to contain the dust generated by grinding fiberglass and sanding fairing fillers.

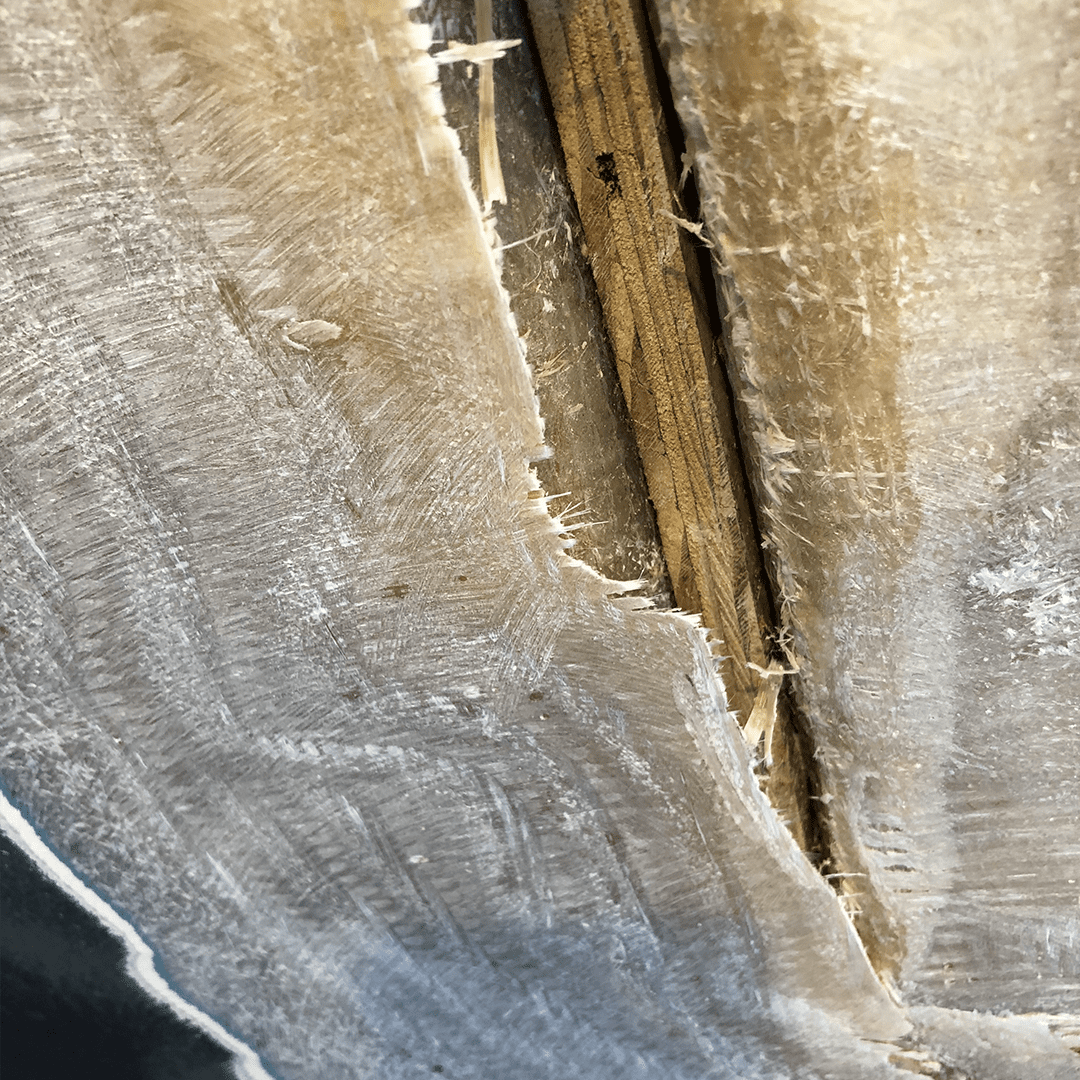

In the case of damage below the waterline the bottom paint must be removed in the repair area before grinding away the damaged fiberglass. The impact from the collision causes the layers the layers of fiberglass cloththat comprise the hull to separate and this delamination can extendthroughmanylayersand spread a surprising distance from the damage visible on the surface.

It must all be removed before patterning, cutting, and laying up the multiple layers of fiberglass cloth to rebuild the hull. Care must be taken in building up the layers. If too many layers are laid up at once the weight of the material will cause it to sag down on a hullside repair, or simply fall off in the case of a bottom repair. In addition, the heat generated by the curing process can cause the fiberglass to become brittle, and in extreme cases, begin to Smoke. Though it will harden, the repair will not be sound.

Structural collision or grounding repairs still require cosmetic work.

Careful patterning and layup produce a structural fiberglass repair that is reasonably close in shape to the original shape, but fairing and shaping work is still required. After an initial grinding, epoxy fairing fillers, and machine andhand sanding need to be done to restore the subtle camber of the bottom or hull side, and seamlessly blend the repair. The bottom is then given a four-coat epoxy barrier coat. Northwest Marine Fiberglass uses Interlux 2000-E epoxy barrier coat, an industry standard for over 25 years. Finally, two coats of antifouling paint are applied.

In the case of a repair above the waterline the faired repair is sprayed with four coats of Awlgrip 545 epoxy finish primer, sanded, re masked, and shot with three coats of LP topcoat or color matched gelcoat, then wet sanded and buffed to blend the repair with the surrounding hull.

Cost of a structural collision or grounding repair

The cost of this type of repair varies widely. If a sailboat keel hits a rock it often just pops off achunk of fairing filler and gouges the lead keel. This type of damage can often be repaired in a day and cost under $1,000 in labor and materials.

A collision with rocks resulting in multiple areas of damage on the keel and bottom of a larger vessel, where the damage extends through all of the layers of fiberglass, can take as much three weeks and 240 hours and cost between $25,000 and$30,000. This is an extreme case, although when a Northwest Marine Fiberglass customer bought a Hurricane Sandy damaged boat and had it shipped from New jersey for us to repair, we had the boat for two months, and it cost more. In addition to the fiberglass damage, we had to find a way to straighten a bent wing keel.

More typically, the structural hull repairs that we encounter at Northwest Marine Fiberglass are in the $2,500 to $12,000 range.

Time and age-related boat repairs (wet deck core)

When bedding fails and water gets into the core between the top and bottom fiberglass skins of a deck or cabin top it can cause serious problems, both to the structural integrity of the deck, and to the interior woodwork. When the core becomes saturated it eventually rots causing the deck to lose most of its strength and become spongy. In addition, water can find a way through the bottom skin and get into the interior. The wet wood turns dark and the finish lifts, causing an ugly blemish on otherwise lovely interior woodwork.Often the water remains trapped in the deck though, or seeps through in an area that is not detected. The boat owner is unaware that a problem exists until it pops up in a marine survey report to complicate a boat sale.

Core repair process

Repairing wet core involves removing hardware, cutting open the top skin, replacing the core, laying up a new top skin, and fairing it and finishing it cosmetically so that the repair blends perfectly with the rest of the boat. At Northwest Marine Fiberglass we use PVC foam core overall, with Coosa Board fiberglass reinforced composite board in areas where hardware mounts. In some few cases where the affected area is contained to a square foot or so around one piece of hardware, say a windlass or windlass control button, and there is clear access to the under skin, like in a large chain locker, it is possible to do the job from below, eliminating the need for time consuming cosmeticfinish work. In most cases though, the job needs to be done from above

Core repair cost

A small, localized core repair, done from above as it is in most cases, can usually be done in three or four days for around $3,000. A more typical situation involves several areas uncovered by a marine surveyor that take a week or two to fix. This might run from $6,000.00 to $10,000.00 In the case where an entire teak deck is removed and replaced the job takes several months and involves as much finish work as structural repair so that the new deck blends with the rest of the boat.

At Northwest Marine Fiberglass most of our customers having a deck core repair job done choose to go with an Awlgrip-Griptex nonskid finish because it is durable, provides excellent traction, and is easy to maintain and keep clean. If, however, the boat owner wants a molded gelcoat nonskid that is identical to the factory nonskid on his boat we have the capability to do that, using Gibco Flex Mold, which costs more. A major job like this, with molded nonskid, is more in the $55,000 to $75,000 range for a midsize sailboat, more for a large powerboat.

FAQ

Northwest Marine Fiberglass does all types of repairs pertaining to the structural integrity and cosmetic appeal of the boat itself. We work in collaboration with a select group of expert individual contractors when a customer needs help with the vessels’ systems; mechanical, electrical, and plumbing, or with rigging.

The cost of a fiberglass boat repair depends on the size of the repair job. Small spot repairs of chips and scrapes in the boats topsides or deck can cost as little as $700 for several spots. A single impact repair that leaves stress cracks in an area less than six inches in diameter might cost around $1,200. A repair job resulting from a collision with another boat, or rocks, might cost $5,000 to $15,000. The cost of repairing a boat involved in a major collision or grounding could cost $100,000 or more.

A fiberglass boat repair can take as little as six hours for a small scrape, to three to four months or longer for a major repair that involves refinishing the entire hull or deck. Most of the repair jobs we encounter take from one to three weeks.

Northwest Marine Fiberglass can match any variation of white gelcoat, and many solid colors except for certain yellows and reds. We can match any paint if the brand is known and still available. We can match many paints where the brand is unknown and custom matching is required. If the finish is metallic, we can match it if the paint color is known and available, however we do not do blended spot repairs of metallic finishes, repainting entire sections or panels instead.

For an estimate:

Hit the Get in touch button on any page on the website or click here to contact us

Email us at [email protected]

Or call (206) 423-7683