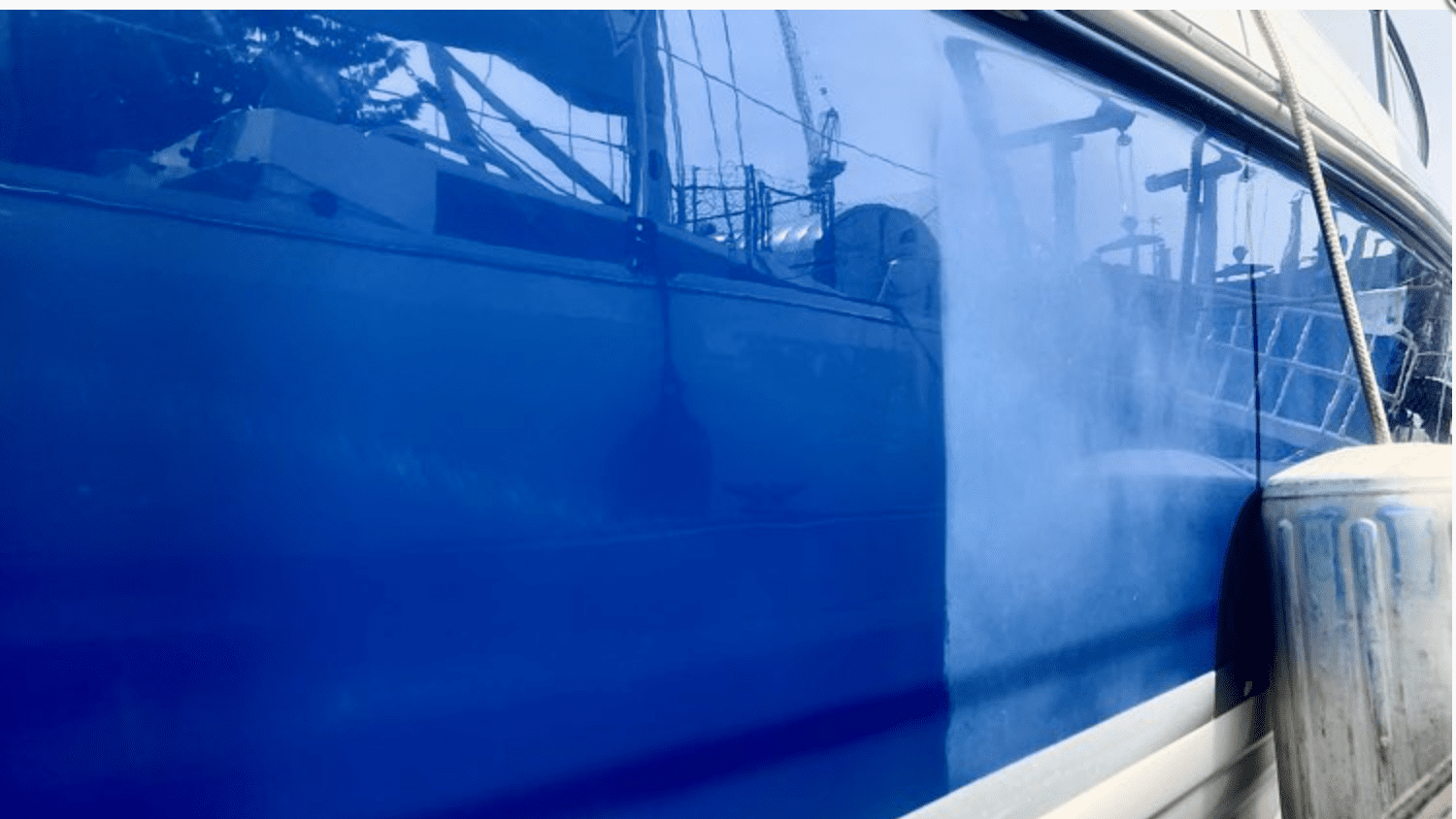

Boat Gelcoat Repair in Seattle

Boat Gelcoat Repair in Seattle

Gelcoat repair is a job that is frequently combined with the bottom painting and hull buffing jobs while a boat is hauled out at the boatyard. Scrapes and chips in the gelcoat are often of no structural significance. The whole point of repairing them is the purely cosmetic one of making them disappear. This means that the color must match, and there can’t be visible irregularities in the surface finish.

At Northwest Marine Fiberglass, perfection is our standard and our expectation. After doing hundreds if not thousands of gelcoat repairs we have mastered color matching and surface blending.

The gelcoat repair process

The first step when making a gelcoat repair is to wet sand and buff a spot on the hull near the area to be repaired to match color to. If this is not done the color will not be correct and will show as a spot matching the faded hull surrounded by a ring of wet sanded and buffed hull. It will stand out. If the color is matched on another part of the boat, it may not be the same color. Hulls and decks can be slightly different colors, as can doors, and hatches.

Gelcoat color matching is a gradual process of adding pigments to a base color and applying them to the test spot until they can’t be seen. Two or three pigments, sometimes more, are used to make even a white. On big jobs, where we will be re-gelcoating large areas of a boat we sometimes use gelcoat that has been computer matched to a gelcoat sample from the boat, but only as a head start in the color matching process. It is never quite good enough and always needs to be adjusted by eye until it is truly a match.

Repairing the gelcoat damage is relatively uncomplicated

The area around the damage is wiped with acetone to clean it, the chip or scrape is dremelled out to remove any loose or crumbling gelcoat, and then filled with a vinyl ester filler. The filler is sanded fair with 80 grit, then sanded out further with 220 grit to provide an area for blending the repair. The area is acetone wiped, masked, and sprayed with four coats of the matched gelcoat and sealed with PVA surface sealer to ensure a hard surface that will not gum up the wet sandpaper. Temperature affects the curing process of gelcoat so it is important to take it into account when catalyzing the gelcoat.

Too much catalyst for the ambient temperature and it will darken the color, not enough and the gelcoat will not cure properly. After curing the repair is wet sanded and buffed to a high gloss finish and waxed. Done correctly it is undetectable.

Gelcoat repair cost

The cost of gelcoat repairs depends entirely on the number and size of the repairs. With a detailed description, ideally accompanied by some photos we can usually provide an accurate estimate in advance of the boat arriving in the yard, or we can easily do one on the spot once the boat is in the yard.. A typical gelcoat repair job involving five or six spots on the hull might cost from $600 to $1,200 depending on the size of the repairs.

FAQ

Gelcoat is the outer surface of most production boats, though some builders finish their boats with an LP paint finish over the gelcoat. Gelcoat is chemically similar to the resin that is used to build the boat, but with pigments and other alterations that make it an attractive and protective finish. In most production boats gelcoat is applied to the highly polished mold, and then resin impregnated fiberglass cloth is laid up on top of it. When released from the mold, the gelcoat is the high gloss surface of the boat.

A typical situation involving five or six small spot repairs on a hull or deck could cost from $600 to $1,200. A repair involving re gelcoating large areas of the house, bulwarks, and decks of a 60ft power boat could be $12,000 to $15,000, or more.

The first step in gelcoat repair is to match the color. In most cases the gelcoat damage is cosmetic, not structural, and getting the color right is key to making the damage disappear. Next, the scrape, gouge, or chip is dremelled out to remove loose and crumbling material, and filled and faired with a waterproof and non-shrinking vinyl ester filler. A blending area is prepared around the area, sanding it with 220 grit, and solvent washing with acetone. The area around the repair is masked, and the color-matched gelcoat is sprayed on. When cured, the gelcoat patch is wet sanded and buffed, which gives it its high gloss finish, and blends it with the surrounding surface.

After matching hundreds, probably thousands of gel coat colors over the last forty we are experts at color matching. We can perfectly match any of the hundreds of variations of white, as well as most blues, greens, and tans. Some reds, grays, and yellows are a challenge, but we can usually get them close enough that the repair isn’t noticeable to someone who isn’t looking for it.

We begin a gelcoat repair using wet sandpaper and rubbing compound to make a spot on the surface near the repair area to match the gelcoat color to. We use vinyl ester filler, sandpaper and sanding blocks to fill and fair the gouge, scrape, or chip. We use masking tape and masking film to protect surrounding surfaces, and we spray color matched polyester gelcoat followed by PVA surface seal to ensure a hard sandable surface. Finally, wet sandpaper and rubbing compound are used to provide the high gloss finish and blend the edges of the repair.

A small gelcoat repair of a chip or scrape or two can take as little as six hours.

We often work on boats needing several repairs around the topsides or deck that can be repaired and gel coated in a day, then wet sanded and buffed to blend them in half a day, a 12 hour job.

Repairing gelcoat problems on a larger powerboat, that require re gel coating large areas of the house, deck, and bulwarks could take three or more weeks.

We have over forty years of experience doing gelcoat repairs. We have done hundreds, probably well over one thousand, gelcoat repairs. We are experts at gelcoat repair, color matching, and surface blending.