Fiberglass Boat Refinishing & Restoration in Seattle

Boat finishes take a beating

UV rays break down the pigments in gelcoats and paints, causing the colors to fade, and can also cause the outer surface to turn chalky and deteriorate. In oxidation, heat and oxygen combine to break down the gelcoat or paint’s molecular structure, eventually leading to a dull porous surface. In addition, wind and currents can lead to docking mishaps, adding scrapes and chips to the hull. When a larger accident occurs, after the structural repairs are made, repainting the entire boat may be the best way to ensure that

the repair is unnoticeable.

A boat can be re-gelcoated

While it is possible to re-gelcoat a boat, we generally only do that on the topsides of smaller vessels, like a 13-foot Whaler or maybe a J-24. Gelcoat does not spray on as a smooth high gloss finish. It is thicker than paint, does not flow out as well. The sprayed gelcoat finish is slightly textured and semi-gloss. To achieve a smooth high gloss finish the gelcoat must be sanded with progressively finer abrasives, from 400 grit through 2000 grit, and then buffed with rubbing compound. While the end result is beautiful this is not a practical way to refinish a larger vessel.

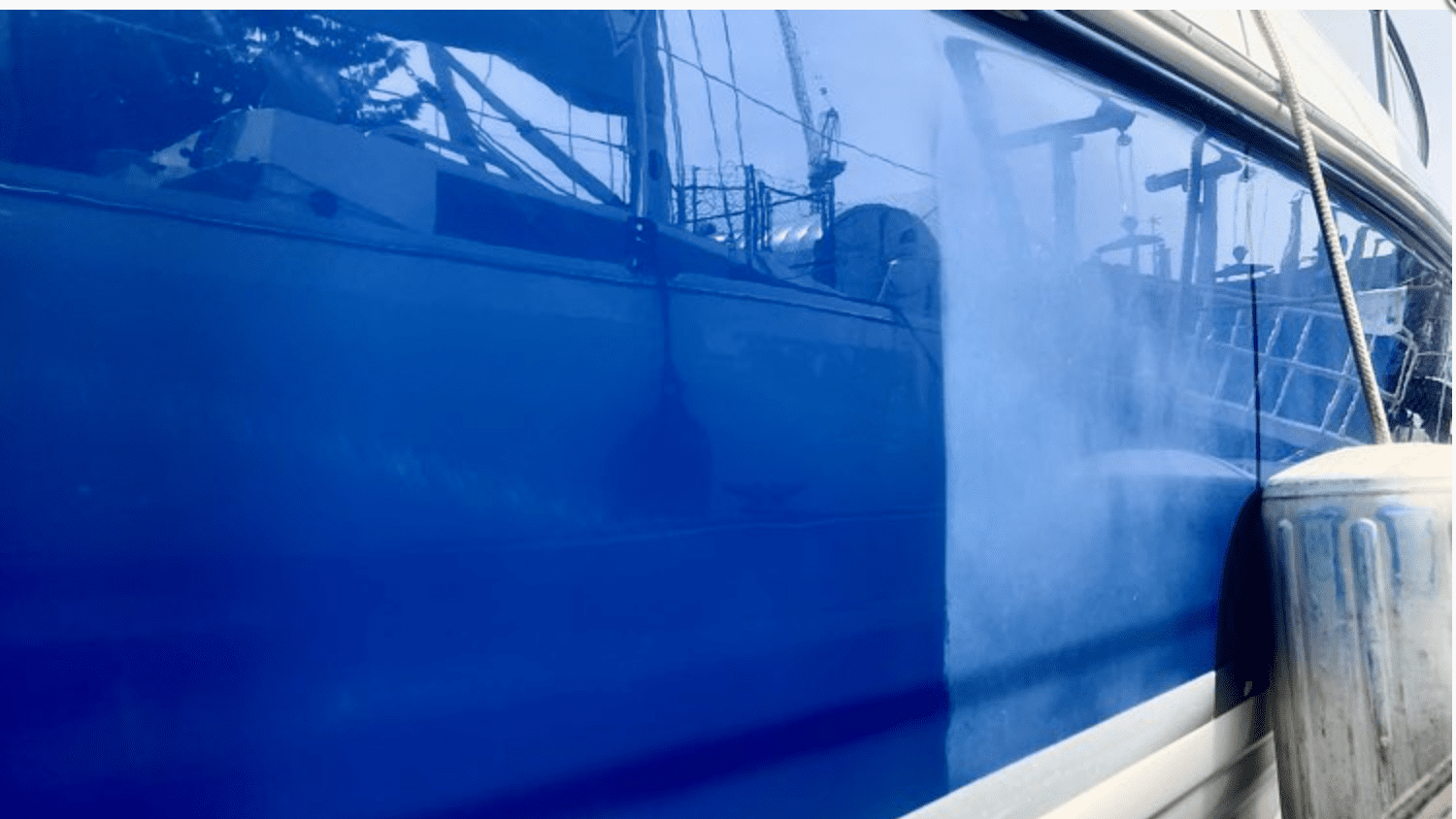

An LP (Liner Polyurethane) paint job is usually the preferred choice for boat refinishing

An LP painted surface is harder and more durable than a gelcoated surface. This means that the painted boat not only retains its color and gloss for much longer than the boat with a gelcoat finish, but is also much easier to maintain and keep clean as dirt and grime can’t get a purchase on the smoother, harder finish. It’s not uncommon for us to encounter boats that we painted ten or fifteen years ago that look like they haven’t aged at all.

At Northwest Marine Fiberglass we’re experts at yacht refinishing and are proud of our LP paint jobs Taking a worn, beat up, or neglected vessel and restoring it to its former beauty is extremely satisfying work. We have years of experience, and after well over 100 paint jobs we still get excited and fully engaged in ever paint job we do.

Our process

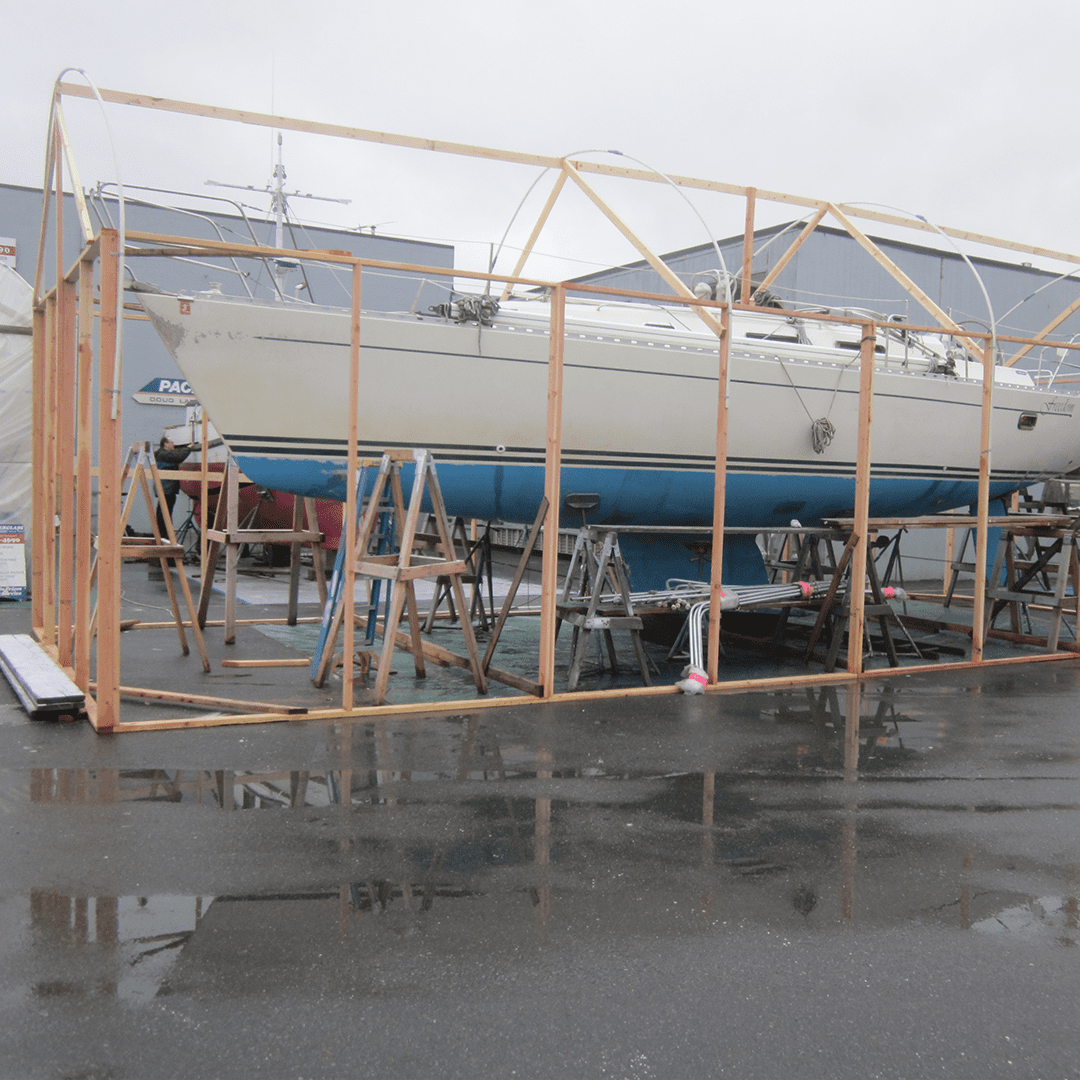

Set up

The first step in yacht refinishing is to set up a heated, ventilated spray enclosure to contain dust and overspray and to provide the optimum environment for the chemical curing the materials require.

Prep work

Hardware in the way of the paint job is removed, along with any vinyl graphics. The hull is solvent washed to remove any surface contaminants, and small nicks and scrapes are filled with a vinyl ester filler prior to sanding with a medium grit paper.

Clean up and solvent wiping with Awl Prep surface cleaner is followed by masking and application of four coats of Awlgrip 545 epoxy finish primer. In cases where the hull

surface is in very poor condition we prime with a high build epoxy primer and sand it prior to priming with the finish primer. The primed hull is inspected, and any surface imperfections are filled with vinyl ester filler, then the primed hull is sanded with 400 grit.

Cleanliness

A clean environment is critical so after priming, the boat is de-masked and the entire shop and staging around the boat is hosed down from ceiling to floor, and the hull is washed with soap and water, then dried with lint free rags. After an overnight dry time, the boat is re-masked, wiped with surface prep solvent and a tack cloth, and is ready for painting

Topcoat application

Three coats of LP topcoat are applied with waiting periods of about 45 minutes between coats. We generally use Awlgrip, but are happy to use other paints like Aexseal if that is the owners preference.

After the paint has been given a couple days to cure, often over a weekend, the boot top stripe and shear stripe are laid out and sanded.

The boat is re-masked, and the stripes are given three coats. Paint thinning, spray gun adjustment, and applicator technique determine the final result, and at Northwest Marine Fiberglass our experience, product knowledge, and care ensure a finish that is beautiful and will hold up over time.

Cost

Topside painting prices vary and depend on the condition of the vessel, but for many boats in the thirty-five to forty foot range the cost of a paint job is $25,000 to $35,000. In the fifty-to-sixty-foot range closer to $40,000.

Boat restoration

At Northwest Marine Fiberglass one of our favorite jobs is one where we refinish a boat from top to bottom, perhaps stripping and re varnishing teak toe rails and cockpit coamings and removing and upgrading hatches, hardware, and portlights. At some point the boat refinishing job crosses over into what we would call a boat restoration. A boat restoration job can take three or four months and cost between $80,000 and $150,000, more in some cases. Because of the expense they don’t come along often, but when they do, we shine.

FAQ

The process of refinishing and restoring a fiberglass boat begins with providing a suitable environment for curing the materials being used, and for containing any environmental contaminants. The boat is enclosed in a heated, ventilated enclosure, and staging is set up around it.

Vinyl graphics and hardware are removed, and the surface is cleaned with solvent to remove any surface contaminants. Flaws like chips and scratches are filled with an epoxy or vinyl ester filler, then the boat is sanded to prepare it for priming. After masking surrounding areas, four coats of epoxy primer are applied.

The primed surface is inspected, and any remaining flaws are filled prior to sanding with 400 grit sandpaper.

The next step is to remove all masking and do a thorough wash down of the shop, staging, and boat, from ceiling to floor. After drying the boat is masked, solvent wiped, tacked off, and given three coats of LP topcoat.

After the topcoat has cured, stripes are laid out, the boat is masked, and the stripes are sprayed.

The final steps are demasking and installing hardware.

After the refinishing process a fiberglass hull or deck will not only look like new, but the finish will be more resistant to UV deterioration and oxidation, so the color and gloss will hold up longer than with a gelcoated surface. In addition, topsides and decks will be easier to keep clean since dirt and grime have a harder time getting a purchase on the harder LP surface. In the end though, how new a boat looks after the refinishing process depends on the condition of the vessels’ hardware. If it is in good condition the boat will look like new.

Northwest Marine Fiberglass uses top quality marine products with a proven track record from start to finish. We use 3M and Mirka abrasives, 3M masking products, 3M vinyl ester fillers, Awlgrip, West System, Maas, and System 3 epoxy fillers, Awlgrip High Build and 545 epoxy primers, and Awlgrip and Alexseal topcoats. On deck we use Awlcraft 2000 acrylic urethane topcoat for its ability to be easily patched and blended, and AwlgripGriptexfor textured nonskid, or Gibco Flex Mold for a molded gelcoat nonskid pattern.

We have over 40 years of experience refinishing boats. Though Northwest Marine Fiberglass opened in 1999, owner Paul Ziegler, still actively participating in the jobs we do, has been refinishing boats continuously since the early 1980s. His skills and knowledge are applied to every job.

We guarantee that we will use only well-known top-quality materials and will follow all manufacturers recommended application procedures. In the unlikely event that there is a problem due to applicator error we will remedy the problem free of charge. (The occasions where this has happened have been very few). If a problem develops due to conditions beyond our knowledge or control (like un-noticeable contaminants or moisture permeating the hull, or a chemical stripper or acid being spilled on deck) we will not feel obliged to make repairs free of charge.

A typical topside refinishing job will take three to six weeks. A full on-deck and topside refinishing job, including stripping and refinishing a teak toe rail and cockpit coaming on a 45’ sailboat could be between three and four months. Refinishing a 65’ powerboat top to bottom can take four to six months.

For an estimate:

Hit the Get in touch button on any page on the website or click here to contact us

Email us at [email protected]

Or call (206) 423-7683